Contact Us

JAE always adheres to the selection of high-quality raw materials, the implementation of strict quality control system, the use of precision machining equipment and measurement and testing instruments, through the advanced product design and manufacturing process, to provide professional knowledge and application services and overall solutions.

We carefully select raw material suppliers, and we need to go through strict supplier approval procedures and incoming inspection procedures before delivery, to ensure the consistency of our product quality. High purity bearing steel can effectively improve the service life of bearings, ensure the high reliability of bearings, reduce the unpredictable shutdown rate of the client. For the quality of the raw materials and outsourcing parts, the company developed strictly regulate incoming goods inspection work program files, including raw materials of chemical composition analysis, microstructure of high and low times inspection and outsourcing parts of the project such as physical and chemical analysis, strictly to ensure the high quality of raw materials used in the manufacture of JAE high-quality bearing products.

JAE through the advance quality planning, from product design and development, raw material purchase, storage, production, to the finished product inspection, packaging, shipping and other processes, all have a quality management system as a guarantee.

At the same time, we have our own physical and chemical laboratory to test and analyze each batch of incoming materials to ensure that each batch is high-quality raw materials.

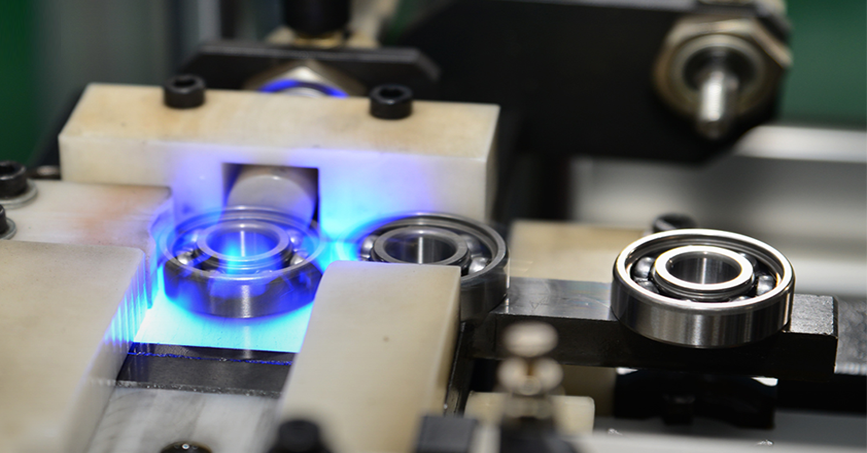

In the process, JAE introduces high precision measurement and testing equipment, and establishes measurement and testing room to ensure the accuracy of process measurement.

JAE China

Jiangsu JAE Transmission Technology Co., Ltd

Address:Gongbo Park, No. 299, Jincheng East Road, Xinwu District, Wuxi City, Jiangsu Province

Zip code:214028

Tel:+86 510-85550008

Fax:+86 510-88998799

Website:www.jaecn.com

JAE Group Headquarters

USA JAE GROPUP CO., LTD>

900 WILSHIRE DR SUITE 202-45 TROY MI 48084